EOQ or EPEI? Which is better?

Most production companies acknowledge the importance of batch sizes. They realize that batch sizes directly contribute to inventory levels, costs, working capital and even capacity. A one-size-fits-all solution, for instance to give every item a batch size of a month, is without a doubt not optimal. There is room for optimization. There are two well-know approaches for optimizing batch sizes: the EOQ-approach and the EPEI-approach.

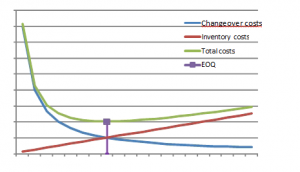

EOQ: balancing the inventory and changeover costs

The EOQ (Economic Order Quantity)-approach uses Camp’s formula to calculate the optimal batch size. This formula balances changeover costs against inventory costs. A smaller batch size means more changeovers and hence higher changeover costs. But in the mean time lower inventory levels and hence lower inventory costs. By applying the EOQ-formula the theoretically optimal batch size is calculated that minimizes the sum of changeover and inventory costs.

EPEI: the smallest batch sizes possible

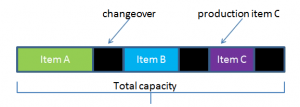

The EPEI-approach starts from the Lean philosophy. The ultimate goal of Lean is to create “flow” and to reduce “waste” and one of the ways to establish this is EPEI (Every Product Every Interval a.k.a. EPEC, Every Product Every Cycle). The main idea is to reduce batch sizes as much as possible, and hence have as many changeovers as possible, to determine a production cycle in which every item is produced exactly once each cycle. The benefits of such a production cycle are clear; it is easy to understand and to implement. People appreciate the simplicity. Besides, it is a great tool to level the workload in production. The repetitive nature of the cycle also gives benefits for capacity planning and supply chain planning in other parts of the supply chain.

It’s not just about capacity, changeover costs may be variable as well.

So what to do? The approaches are different but both claim to establish optimal batch sizes. Let’s investigate the main differences to determine which approach is the right one.

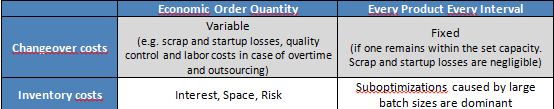

The EOQ approach assumes that changeover costs are variable. More changeovers mean higher changeover costs. The EPEI approach does not agree. More changeovers do not lead to higher changeover costs, at least if one keeps within the set capacity. In that case the available capacity is just used in a different way without increasing the cost basis. Both approaches are sometimes right and sometimes wrong.

There are different types of changeovers costs. One can distinguish between for instance labor costs and scrap costs, but one can also think of costs for quality control when due to legal requirements each batch needs to be inspected separately. To determine optimal batch sizes it is important to only take into account the variable changeover costs, the costs that are directly influenced by more or less frequent changeovers.

The labor costs of changeovers, basically the time operators are occupied by changeovers, is essentially nothing more than lost capacity. These costs are often, at least in the short term, not variable. Production capacity is set and cannot be changed. Or it might be changed but only in large steps by deploying extra shifts. If these costs are indeed not variable, then these should not be taken into account for determining optimal batch sizes. However, if overtime occurs on a structural basis, if capacity is outsourced or if the machine is a bottleneck, then the labor costs can be seen as variable. In those circumstances every added hour of changeover time immediately effects the bottom line of the company by either increasing costs or lost revenue.

Scrap costs are the costs for scrapping material due to changeovers. When a machine is shutdown, often materials are left behind which cannot be used anymore. These materials have to be discarded and this creates waste. When restarting the machine more losses can occur. The first items produced on the machine might not be produced correctly or even damaged. These items have to be discarded as well. Scrap and startup losses are typically variable since these are dependent on the number of changeovers.

Inventory costs are more than interest, space and risk

The EOQ approach and the EPEI approach have also a different view on Inventory costs. In the EOQ approach one usually considers the inventory costs to consist of three components, interest, space and risk. This approach probably underestimates the due to costs. Large batch sizes not only effect the stocking point directly after the machine, but can also cause disturbances and suboptimizations in the entire production process or even the entire supply chain. The Lean approach considers these disturbances and suboptimizations to be dominant. Therefore addressing these issues is top priority.

The best approach depends on the situation

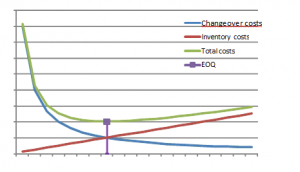

Concluding, for determining the optimal batch size only the variable changeover costs should be taken into account. Sometimes labor costs are variable, and sometimes these aren’t. Sometimes scrap costs are variable, and sometimes these are negligible. If there are no or negligible changeover costs, then the EPEI approach should be followed. If, however, there are substantial variable changeover costs, then the EOQ-formula is the way to go. In both cases it is wise to look at the inventory costs in a more realistic perspective than just interest, space and risk, and to keep in the back of your mind that large batch sizes can cause negative side-effects in other parts of the supply chain.

It is good to be aware of the fact that both EOQ and EPEI approaches have extensions making them applicable in complex situations. For instance, an adapted version of the EOQ formula can be used in case of product groups for which the changeovers within a product group are limited, but between product groups significant. And using the EPEI approach does not necessarily imply that every slow mover should be produced every cycle following the pace of the fast movers. While using the EPEI approach one can still take variable changeover costs and individual item characteristics into account. Although, honestly speaking, in those cases EPEI starts to lose her appealing simplicity and starts to resemble the EOQ approach.

Do not optimize given the constraints, but optimize the constraints

To conclude, Lean (and EPEI) is more of a religion than a formula. The essence of Lean is not to optimize given the constraints, but to optimize the constraints. Continuous improvement. After implementing EPEI you cannot lie down and relax, thinking all hard work is done. Instead, you need to proactively keep looking for methods to reduce changeover times and costs even further in order to reduce batch sizes even more. That said, continuous improvement is not patented by Lean, so it is legally allowed to use the EOQ-formula and in the mean time look for ways the reduce changeover costs.