The winning supply chain of the future

Back in the early nineties, Steve Jobs already realized that a well-designed, effective supply chain was paramount to Apple’s success. Hence he actively participated in managing it. Last year he was succeeded by the man who had been responsible for the supply chain for years. Apple’s story shows that supply chains need not merely be a source of costs, but can fundamentally contribute to a company’s success. This article describes six guiding principles to design a winning supply chain. The starting point is the need of the critical customer.

The supply chain in a changing world

Designing a supply chain starts by looking out the window; to the environment in which it operates:

Firstly, there is the volatile and impossible to predict market demand, with increasing customer expectations. The customers use different retail channels like the traditional shop, the internet, the smartphone or the iPad. These channels are increasingly mixed (the multi- or omni-channel principle).

Secondly, the life cycles of products keep decreasing. Not merely those of high tech and innovative products like smartphones; the assortments of functional products like candles changes faster as well. This has a big impact on production and the logistics structure.

Thirdly, supply chains are becoming more complex due to specialization and internationalization. In the nineties, the trend towards “back to core business” started and it is still progressing. The consequence is many – often international – chain partners. Grip on supply chain risks and supply chain control have become major themes as a result.

Cost and quality remain important and key to success, but are no longer ‘differentiators’ and have degraded to ‘qualifiers’. A bigger effort is needed to surpass the competition. Many companies therefore try to amend the design of their supply chains to cope with the changing world, as mentioned above. And some of them are doing extremely well, Apple being an excellent example.

One thing is certain: a well-designed supply chain can make the difference between winning and losing!

The optimal supply chain

So what does the optimally designed and future ready supply chain look like? To answer this question we need to take a step back to the essence of supply chain management. How can one best meet the customer needs? And does one need stock to do that? If so, where?

There are two valid reasons for keeping stock:

- To guarantee availability of products

- To be able to deliver products on time to the customer in case the required delivery time is smaller than the time needed to acquire or produce the products

- To deal with demand uncertainty by keeping safety stock

- To benefit from efficiencies

- Benefits of scale in procurement

- Efficiency in the inbound flow of goods

- Dealing with variability in the organization

In general, consolidating stock in the supply chain needs to be stimulated. In principal, any supply chain with more than two tiers (i.e. more than two stock keeping points in a row) is inefficient and sub-optimal.

In real-life we come across many sub-optimally designed supply chains. Quite often organizations are not ‘aligned’, neither internally nor externally; this can be historically grown or caused by different ‘blood types’ in the organization, or by many (international) supply chain partners combined with a lack of integration and communication. Besides, in too many organizations people reason from their own perspective, while for supply chain optimization one needs to “think differently”; from a wider perspective. Culture, leadership and management style are therefore key to designing the optimal chain.

Furthermore, logistics in many organizations is merely seen as a source of costs and not as a means to achieve the company strategy and meet customer requirements.

The perfect chain is therefore not in sight. While at the same time it becomes more and more important to surpass the competition.

Six strategic guiding principles

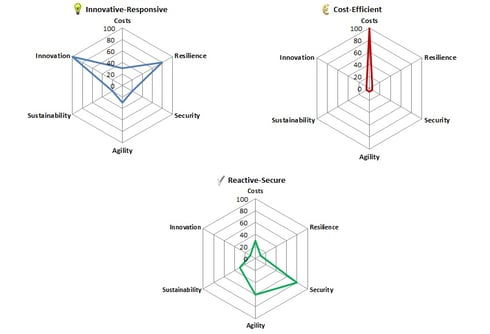

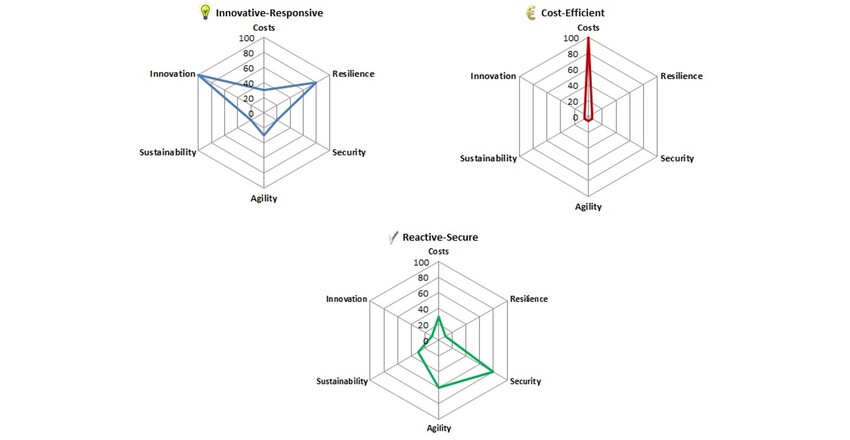

The winning supply chain of the future makes the turn from the traditional supply chain, which is cost-driven and strategically decoupled, to the new supply chain, which is value-driven and strategically coupled. Steven Melnyk et al. (2010) did an intensive survey to the supply chain of today and tomorrow in their paper “Supply Chain Management 2010 and beyond”. Based on that research, six guiding principles have been defined for designing the supply chain: Cost, Agility, Security, Resilience, Sustainability and Innovation.

To design an effective supply chain, an organization needs to focus on a combination of two or three of these guiding principles.

Guiding Principle Costs

Goal

- Cost reduction

- On time and reliable deliveries

Key Characteristics

- Standardization of products and processes

- Waste reduction

- Focus on reducing variability in the supply chain

Guiding Principle Agility

Goal

- React quickly on fluctuating demand (volume and mix) against acceptable costs

Key Characteristics

- Exchange information with the key chain partners

- Capacity flexibility

- Small batch sizes

- Careful supplier selection

Guiding Principle Security

Goal

- Assure that products pass the supply chain unaffected

Key Characteristics

- Transparency in the chain through integrated IT systems

- Certification of chain partners

- Supply Chain Risk Management

Guiding Principle Sustainability

Goal

- Minimal impact on chain resources, with ‘cradle-to-cradle’ as the ultimate goal

Key Characteristics

- Sustainable product design, packaging materials and processes

- Certification and audits

- Reverse logistics

Guiding Principle Resilience

Goal

- React quickly on disturbances and events

Key Characteristics

- Transparency in the chain through integrated IT systems

- Deployment of added resources if necessary

- Scenario planning (“what-if” scenarios)

Guiding Principle Innovation

Goal

- Deliver innovative products, processes and services.

- Including new production or distribution technologies

Key Characteristics

- Mutual design with chain partners

- Intensive information exchange

Source: Melnyk et al. (2010)

Wisely chosen combinations create less dependency and an increased diversity to the customer. Here it is key to choose a mix based on the customer needs, for which he is willing to pay so that the company can gain a competitive advantage.

The chosen guiding principles also serve as the starting point for the design and control of the logistics footprint. Subsequently, the ICT systems and organization can be designed and implemented.

Three examples of combining the guiding principles to gain a competitive advantage. Many high tech industry companies use the Innovative-Agile chain, pharmaceutical companies the Resilience-Security chain. The cost-efficient chain exclusively focusses on cost reduction, for example a supply chain of a discounter. Focusing on only one guiding principle creates dependency and increased vulnerability in changing markets.

Key elements of supply chain strategy

As stated before, a well-designed supply chain can make the difference between winning and losing, provided that this chain is strategically coupled and value-driven. The future winners are aware of the environment they operate in and choose a clear strategy with the right guiding principles to shape their supply chains.

Culture, leadership and management style are key in designing the optimal chain. An important element is to think differently; “presumed logical thinking” is a common pitfall for change. Superior logistics requires out-of-the-box thinking. Simulation and serious gaming have proven to be powerful assets in creating visibility and change.

To summarize the key steps:

- Take the company strategy as a starting point; what is the added value for the customer?

- Determine the guiding principles per product market combination; preferably a combination of 2 or 3 principles

- Design the logistics footprint and its control

- Finally, design the ICT systems and the organization